CA Cycleworks Products - Exact Start Hi Cap Cable Kits - QR Fuel Connectors - Motool Digital Suspension Tool

Exact Start Aerospace Quality Hi Cap Starter Cable Kits

Making V Twin Motorcycles all over the world fire into life instantly since 2015

After seeing more expensive kits and cheap kits from a few home crimpers using the same inferior terminals that the OEM cables use we decided to use our automotive industry experience to source some high end aerospace quality starter cables to give customers the best product quality Vs price.

We source from a BAE aerospace cable supplier in the UK and design each kit for each specific model that we cover.

This included even having all our terminals manufactured to order from oxygen free copper and then tin plated. Even our standard straight terminals are bespoke and manufactured to achieve an increased cross sectional area and subsequently the best possible results in performance and quality.

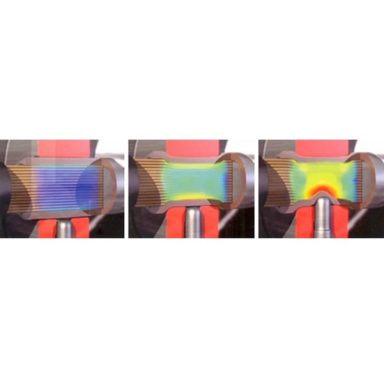

The crimping process uses a 35 tonne fusion crimp press and the cables are then double sealed with a high quality bonded shrink wrap, the terminals having no holes to stop moisture ingress.

The cable design is specially developed for flexibility whilst not deteriorating through stress when bent due to the special design of the thin copper strand weave.

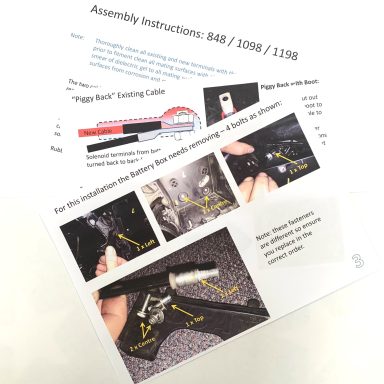

Where OEM cables are spliced into the loom our cables simply 'piggy back' them so as not to require any splicing into our sealed cables which would allow moisture ingress - this also simplifies fitment. Where OEM cables are not spliced then all cables can simply be swapped with the OEM fitments.

Cable Kit Images...

Our Cable Kits come with everything you need for a professional quality instal & come with photo instructions too

Exact Start Premium Starter Cable Upgrade Kits

Specification and Design Criteria...

Cable Choice:

Investigation of a competitor’s choice of 25mm² cable was looked into first due many reports of fitment difficulty: we found the following information...

An industry standard voltage drop of 3 to 4% was generally regarded as acceptable.

Voltage drop over an average length 25mm² cable in our application is 0.02V or 0.17%

Voltage drop over an average length 16mm² cable in our application is 0.03V or 0.25%

Therefore both cables far exceed this requirement meaning 16mm² cables are more than fit for purpose and indeed over engineered for our application; as long as the life time quality with no deterioration could be achieved.

Cable life:

To ensure a lifetime of service with no deterioration we approached a specialist rail / aerospace industry cable/crimp manufacturer and specified what I believe to be the best anti vibration / anti fatigue cable system available. Not being satisfied stopping there I commissioned a double sealed system where the cable not only seals against the crimps, but is double sealed with a special bonded heavy duty heat shrink on each join. Further to this I had them remove the inspection hole in their high quality copper terminals to give a system that would remain fully sealed for life in the hardiest of conditions – designed to achieve no deterioration in current flow.

Cable design:

Our supplier already had a specialist cable developed for the rail industry which employed a special rope weave within its construction for extreme anti vibration qualities. Straight cable when bent can fatigue the copper, hence reducing the current flow. The rope system made up of hundreds of micro 0.2mm² high quality pure copper strands does not suffer this. So, we had our perfect cable. One minor problem, it was only available in black. Why not make the +’ve cables the correct colour, so we did!

Kits for 'naked' bikes are supplied with black heat shrink just in case the customer prefers black on the positive cables.

Terminals:

Rail industry leading heavy duty ‘seamless’ copper terminals were chosen for maximum electrical conductivity adjusted to our design & cross sectional area requirements. These undergo a 35 tonne specialist crimp process which gives excellent conductivity and an industry leading strength – they will not fail: my supplier’s crimps have proven to be stronger than the cable itself during testing!

Each terminal is designed for optimum performance requirements and bespoke designed specifically for fitment to individual models; they are then annealed and tin plated to protect the longevity of the terminals performance.

Fitment:

Everything is included in the kit to aid fitment including Photo Instructions, Wet & Dry paper, Tie Wraps, Isopropanol Wipes, Tubes for the Battery nuts & Dielectric compound. We even include brass half nuts where they may be necessary for the terminal posts on the Solenoids to effectively give more thread when cables are piggy backed.

© Copyright. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.